Certificates & Transparency:

SBP® Sustainable Biodegradable Products™

Read our product transparency information

| PIT®: PRODUCT INFORMATION TRANSPARENCY ™ |

|---|

| SBP® Sustainable Biodegradable Products |

| Fiber Content: NON-GMO Sustainable Industrial Hemp grows without the need of harmful herbicides and pesticides; hemp is planted in dense crops not allowing sun light to penetrate, which reduces weed growth by 95%, eliminating the need for herbicides. No pesticides are used due to the inherent properties contained in the plant itself. Hemp is commonly used as a companion crop bordering family gardens as a deterrent to insects and infestations. Hemp is an ideal rotation crop due to its long taproot structure that helps retain topsoil, while also replenishing soil quality due to the natural leaf composting that regenerates vital elements in the soil. Hemp does not require irrigation unlike other natural fibers. The unique inherent characteristics of the fiber of hemp have the additional ability to suppress the growth of harmful bacteria and fungi, making it the ideal “fiber for our future. ™” As a result of the above, hemp does not require organic growing certification. Market demand has pushed us to now have Certified Organic Hemp. |

| Anti-Microbial Properties: Naturally Inherent throughout the plant |

| UV Factor: SPF 15 |

| Infrared Resistant: Yes |

| Origin: China EARTH” and other global locations. |

| Growing Practices: Companion planting, bio- organics small coops of family farms, large commercially grown. Industrial Hemp as historically grown, seed is broadcasted, approx. 120 plants per square meter. Planted densely to allow the plant to grow reaching towards the sun which prevents branching. The high-density planting prevents the sun from penetrating, which prevents weeds. Minimal water consumption is needed until the plant has grown enough to prevent sun penetration, which allow the soil to stay moist. |

| Harvesting: Manpower, the leaf is removed from the stalk and left in the fields to biodegrade and replenish vital nutrients to the soil. Modern day harvest machinery swath cuts stalk to stand in a tepee formation to dry. |

| Employment Numbers: Countless family farms throughout the region grow hemp, adding value to their current agricultural products. |

| Transport: Brought to a central location to be delivered to the factory. |

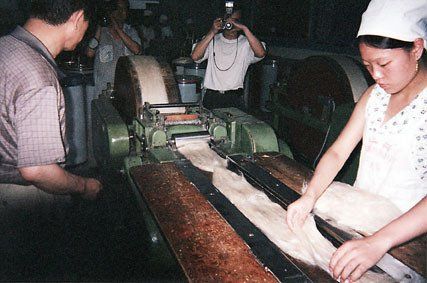

| Processing: Many 1st step methods can be used: Submerge hemp stalk in man made water ponds for retting process (the removal of bark from woody core) sun dried; the fibrous skin is then hand pealed and baled for transportation to the fiber processing factory |

| Degumming Ribbon Fiber: Degumming is required to remove the cellulose and lignin that are contained in ribbons of pealed bark. Effluent waters (plant sludge) are filtered using a government approved purification system mandated by the Chinese government under an environmental policy implemented in 1995 requiring all effluent factory water to be purified via a government approved purification system located at the factory thus creating a closed loop system. When visiting we can see firsthand the various pools for cleaning as it works it’s way down to the final stage, where you can drink the crystal clear water. |

| Fiber preparation: Fiber is mechanically carded separating the short and long fiber. Short fiber is used in the blendi blending of yarns with organic cotton, while long fiber stands alone. |

| Certifications: All Cotton and all Hemp is certified organically grown by Control Union according to the NOP National Organic Program and GOTS Global Organic Textile Standard certification. It is not possible to certify a garment to be organic, it is only the fiber from a plant that can be certified, like food products. Fiber is from a plant that can be certified if required, such as for the growing practices of cotton due to the harmful amounts of pesticides and herbicides. Other certifications for our COTTON YARNS are “Global Organic Textile Standard” GOTS for the processing of fibers from certified organic agriculture. SBP® Sustainable Biodegradable Products PIT Product Information Transparency; Organic 100 content Standard Organic Blended |

| Yarns/ Spinning: Ring spun, wet spun, open end, dry spun. |

| Weaving Sizing Agents: Potato Starch is used as a sizing agent on the warps to make the yarns smoother for weaving. |

| Factory Conditions: ISO 9001:2000, 25 workers or more requires ACFTU China Federation of Trade Unions |

| Factory Effluent Water: 14year government policy- All water must go through purification by approved government purification system. Closed Loop process. Research: China’s Environmental Impact Assessment (EIA) System |

| Factory Workers Benefits: |

| Housing: Factory provides apartments to workers that they will own at retirement, which is a similar form to the American Social Security System. |

| Daycare: Provided by factory |

| Hospitals: Clinic provided by factory which is mandatory by the Chinese government. Government requires all factories to pay 75%, employee pays 25% |

| Schools: All factory workers children attend 6 years primary school, 3 years middle school, on factory site. |

| Factory Benefits: Transportation to factory provided by factory, 6hr days with hour lunch, half days on Saturday during holiday production season, one cooked lunch, Paid approximately $700. USD per month; Paid National Holidays Total 91 days per year. 98 days paid maternity leave. One hour fully- paid for breast feeding up to 1 year. Retirement age is 55 years. |

| Community: Building requirements mandate that all water is solar heated. Our factory provides community activities such as talent shows, karaoke, theater, and wedding ceremonies. The President of the factory is loved and respected by his community of workers. |

| Finishing: |

| Bleaching: Peroxide |

| Softener: Cationic, which is a water soluble. |

| Dyes: Fiber reactive low impact dyes used for 100% Hemp, Hemp/ Organic Cotton Testing: Fire rating Cal 117, NFPA 701, Martindale Abrasion ASTM D-4966, Seam Slippage ASTM D-1683, Tensile Strength ASTM D-5034-08, Color Fastness AATCC16, Pilling Resistance ASTM D-3512 |

- Fabric Tests = Have been performed on many of our fabrics. All fabrics meet the required fire requirements:

- Cal-117

- MSDS= Material Safety Data Sheet

- VOC= Volatile Organic Compound

- SBP® Sustainable / Biodegradable Products, considers corporate responsibility and PIT:

- Product Information Transparency to be an essential part of any company or product.

- Manual labor has a social aspect, creates jobs, and has a low carbon footprint.

This Product Information Transparency label has been developed by:

EnviroTextiles LLC / Barbara Filippone President / Product Development

EnviroTextiles LLC info@envirotextiles.com / www.envirotextiles.com P: +1-970-945-5986

September 21, 2022

EnviroTextiles

Dear Barbara Filippone,

We've got exciting news: The USDA BioPreferred® Program is celebrating 20 years as the Federal Government's official advocate and market accelerator for biobased products.

As a Program Participant, you have been instrumental to our success, and we want to extend our sincere thanks for your involvement and support. We also want to recognize you as a BioPreferred Program Champion and show our appreciation for businesses like yours that have shown faith in our mission.

To mark the 20th Anniversary, we are sending a special "Champion" promotional badge for use in your marketing and communications. This badge signifies your long-term commitment to using renewable materials, reducing our reliance on petroleum, supporting the bioeconomy, and bettering the planet. (Attached are both jpg and png formats for your convenience.)

USDA's BioPreferred Program was first introduced in the 2002 Farm Bill with the goal of increasing the development, purchase, and use of biobased products. It requires federal agencies and contractors to give purchasing preference to biobased products.

As you know the USDA BioPreferred Program also includes a voluntary certification and labeling initiative for biobased products. You may recall last year we celebrated the 10th Anniversary of our USDA Certified Biobased Product Label.

While we've accomplished a lot in 20 years, we're even more excited by the momentum and growth we see in the bioeconomy and its prospects for the future. Here's what we're seeing:

- Over 7,000 products in our catalog eligible for federal purchasing preference across 139 product categories

- Increased reporting of biobased purchases by federal contractors

- Continued increase in applications for certification

- Over 6,200 USDA Certified Biobased Products

- Participation from businesses in 47 countries and more than 1,500 companies in the U.S.

- A 536% increase in certification of upstream materials from 2015 to 2022! This includes binders, chemicals, cleaner components, fibers and fabrics, foams, lubricants, oils, fats and waxes, paint and coating compounds, personal care products components, plastic resins, rubber materials, and textile processing materials.

Over the next several months, we will be sharing more exciting news about the Program as we continue our celebration. Please follow us on Twitter and LinkedIn for regular updates.

Again, thanks. We hope you display your BioPreferred Program Champion badge with pride.

Very truly yours,

Andrew Jermolowicz

Director, Business Development Division

Rural Business-Cooperative Service

USDA rural Development

EnviroTextiles Fair Trade Practices

Fair Trade

Fair trade is an arrangement designed to help producers in growing countries achieve sustainable and equitable trade relationships.

The design of the Fairtrade Standards is to assure that producers receive prices that cover their standard costs of sustainable production, provide an additional Fairtrade Premium which can be infused in projects that improve social, economic, and environmental development.

Fair trade is a global movement made up of a diverse network of producers, companies, consumers, advocates, and organizations putting people and planet first.

Fair Trade vs. Free Trade

Free trade emphasizes the need for less borders, restrictions, and tariffs on goods and services passing through countries and continents. Meanwhile, fair trade involves making certain that the laborers behind these goods and services are treated without bias and that human rights are advocated throughout the supply chain.

How Envirotextiles participates in free and fair trade with suppliers, customers, and employees.

EnviroTextiles uses Fair Trade in our Manufacturing and Importing as a trading alliance based on conversation, transparency, and consideration which seeks greater equity in international trade. We contribute to sustainable development by offering better trade conditions and securing the rights of marginalized producers and workers by offering reasonable compensation to all regularly employed persons for services rendered, contributing to a satisfactory quality of living for all employees.